How To Cut 1/8 Inch Steel Plate

1 / eleven

Cut Metal Fast

There'due south cypher incorrect with using a adept, sometime-fashioned hacksaw, simply in that location are faster, easier ways to cut metal. We'll show you power tool tips and techniques for cutting the types and thicknesses of metallic that DIYers handle the most.

And whether you lot'd similar to build custom cars or just fix a cracked backyard mower deck, learning to weld gives your DIY game a serious heave.

2 / 11

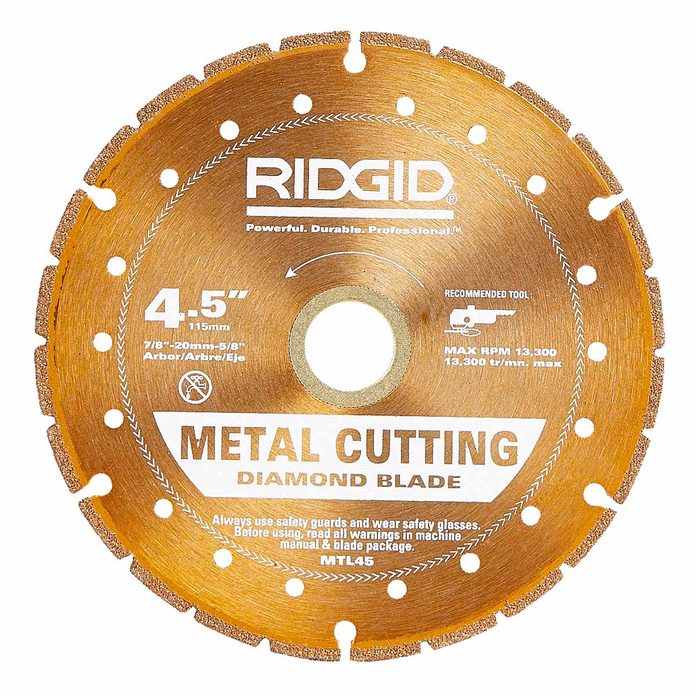

Ditch the Abrasive Grinder Discs

An angle grinder fitted with an abrasive metal-cutting disc works well to cut all kinds of metal, including bolts, angle iron, rebar and even canvas metallic. But the discs clothing down quickly, cut slowly and shrink in bore as you use them. Instead, nosotros recommend using a diamond bract that's rated to cut ferrous metallic. These will last much longer, cutting faster and cleaner, and wear down much slower than abrasive discs.

3 / 11

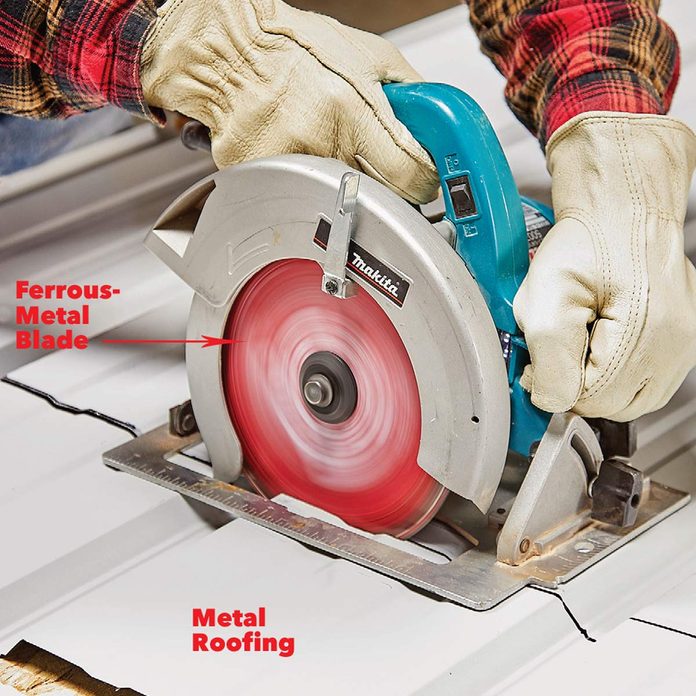

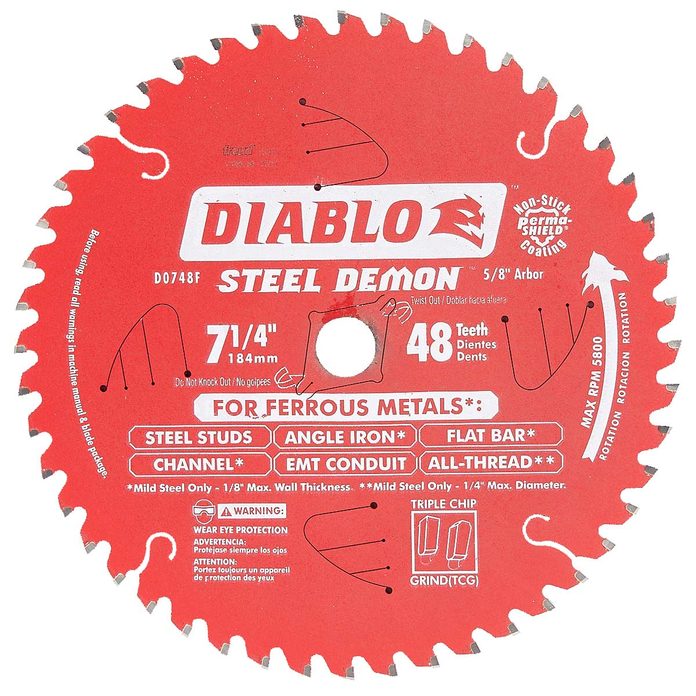

Cut Metallic with Your Circular Saw

Information technology may not be an obvious choice, but fitted with the correct blade, a round saw is a neat metallic-cut tool. In our examination, it cut through rebar like a hot knife through butter. Yous can cutting mild steel up to about 3/8 in. thick using a ferrous-metallic-cutting blade. Exist conscientious, though! Hot metal chips will wing everywhere. Put on your safety gear, go on bystanders away, and encompass annihilation yous don't want coated with metal chips. There are two types: inexpensive steel-tooth blades and carbide-tooth blades. Carbide-molar blades are more expensive but will final longer.

It doesn't matter if you're a long-fourth dimension DIYer or merely starting out on some projects, there are some tools of the trade that are crucial in getting jobs washed.

iv / 11

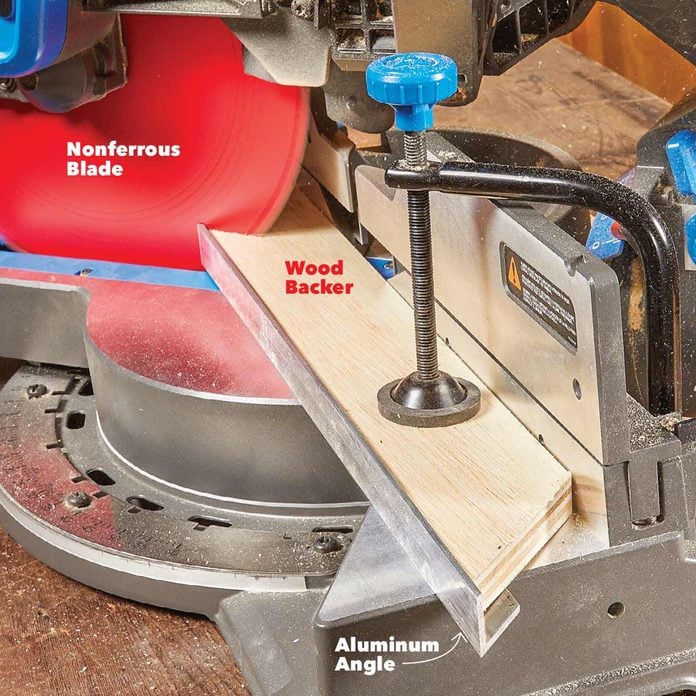

Cutting Aluminum with Your Miter Saw

Making accurate cuts on aluminum rods, tubes and angles is easy with a miter saw and a blade designed to cut nonferrous metallic (check the label). If the motor housing on your saw is open up and could collect metal chips, tape a piece of cloth over the openings to protect the motor windings and bearings while you cut the aluminum. (Remember to remove it when the saw goes back into regular service or the motor volition overheat.) Trapping the aluminum with a forest backer as shown reduces the danger of flying metal shards and makes it easier to concur the metal in place for cutting. This tip is especially important when yous're cutting thin-walled pieces. Without the bankroll lath, the blade volition often catch on the metallic and distort it and go far unusable.

five / 11

Tips for Cutting Metal Safely

Cutting or grinding metal sends tiny fries or shards of metal everywhere. And they can be hot and sharp. To avert center injuries, cuts, burns and other injuries from cutting metal, follow these rules:

- Read and observe safety precautions printed on metal-cutting discs and blades.

- Wear safety glasses, a face shield and hearing protection.

- Cover all exposed skin with gloves, long-sleeve shirt and pants.

- Allow freshly cut metal to absurd before touching it.

- Wear gloves when handling metallic that could accept precipitous edges.

- Securely clamp metal before cutting it.

- Never let anyone most you while you're cutting metal unless they're wearing hearing and eye protection.

6 / eleven

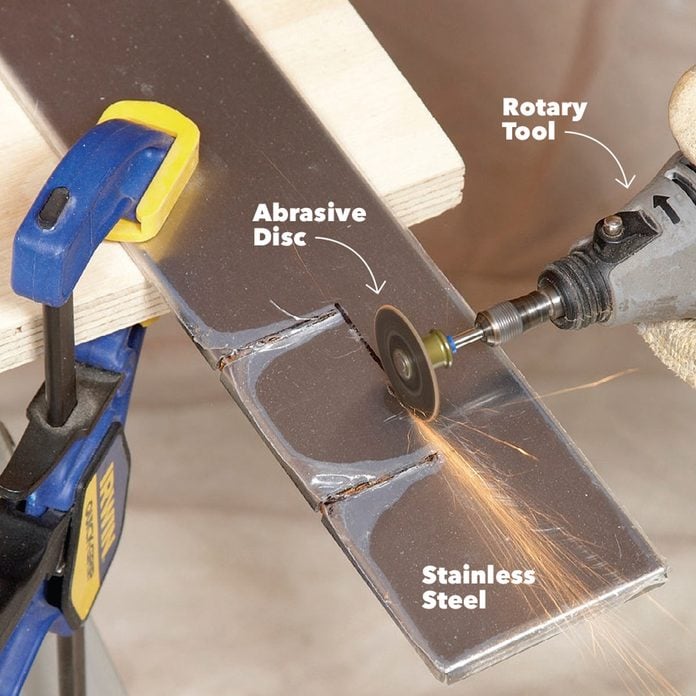

Cut Stainless Steel with a Grinding Disc

There are many types of stainless steel, and some hard varieties are challenging to cut. For small jobs like cutting stainless steel backsplash tiles, a rotary tool fitted with an annoying metal-cutting disc works fine. For larger jobs, mountain an abrasive disc in an angle grinder.

7 / 11

Simple Score and Snap

Siding contractors and roofers routinely score and snap aluminum siding and flashing to create straight, precise cuts. And you lot tin apply the same technique anytime you need a directly cut on aluminum or other calorie-free-judge sheet metal, even steel. Clamp or concord a straightedge or square along the cutting marks and score a line with the tip of a sharp utility knife blade. Then bend the canvas back and along a few times to snap it. You lot tin use the same trick to cut metallic studs. Snip the two sides. Then score a line betwixt the cuts and bend the stud to suspension it.

8 / 11

Become into Tight Spots with an Aquiver Tool

When access is tight, or you demand to brand a flush cut, an oscillating tool fitted with a metallic-cutting bract volition solve the trouble. Corroded mounting nuts on toilets and faucets are piece of cake to cut off with an oscillating tool. You lot can also utilize an aquiver tool to cut plumbing pipes, automotive bolts, nails and other metal objects in places where a larger tool wouldn't fit. Just make sure the blade is intended to cutting metallic.

nine / 11

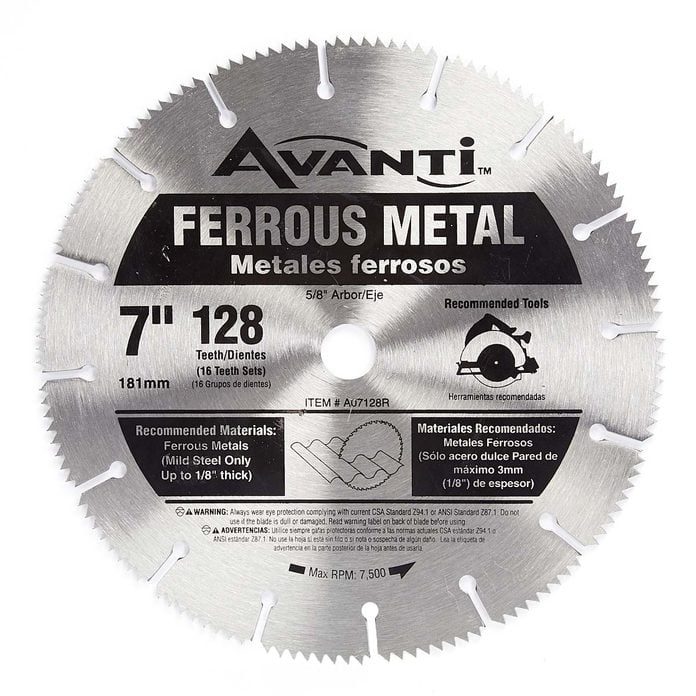

Match the Blade to the Metal

With the right bract or grinding disc, you can cut most whatsoever kind of metal. The fundamental is to match the blade to the material. There are ii types of metal: ferrous and nonferrous. (The term "ferrous" is derived from the Latin word "ferrum," which means iron.) Whatever metal that contains iron is a ferrous metal and requires a ferrous-metalcutting blade. Steel angle iron, steel roofing, rebar and steel bolts are examples of ferrous-metal building materials. Most metal-cutting blades and discs are labeled for cutting either nonferrous or ferrous metallic.

The two most common nonferrous metals DIYers demand to cut are aluminum and copper. Nonferrous metals are ordinarily softer and easier to cut than ferrous metals.

10 / 11

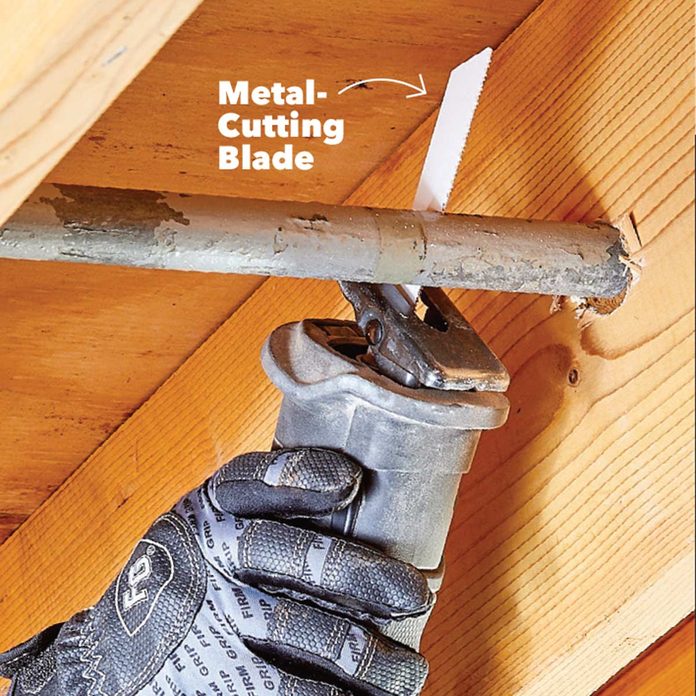

Cutting Smarter: Apply a Reciprocating Saw

The side by side time you reach for your hacksaw, catch your reciprocating saw instead. Mount a metal-cutting blade in your reciprocating saw and you've got the ultimate power hacksaw for cutting bolts, rods, pipes and angle fe. A recip saw with a metalcutting blade also works peachy for remodeling demolition when there are nails and pipes to cut off. Here are a few tips for cutting metal with a recip saw:

- Set your saw to direct rather than oscillating if at that place's a choice.

- Extend blade life by keeping the saw's speed deadening.

- Choose a blade with 20 to 24 TPI (teeth per inch) for thin metal, 10 to 18 TPI for medium-thickness metal, and about viii TPI for thick metallic.

- Buy bimetal or carbide-tooth blades for longer blade life.

xi / xi

Cutting Metal Board and Mesh with a Grinder

Metal lath and hardware textile can be cut with a can snips, simply at that place'due south an easier mode. Mount a diamond blade in your angle grinder and use information technology like a saw to cut the mesh. Nosotros recommend using a diamond blade that's labeled as a ferrous-metal-cutting blade, but many tradespeople employ a regular masonry diamond blade with proficient results.

Originally Published: April 18, 2018

Source: https://www.familyhandyman.com/list/10-easy-ways-to-cut-metal-fast/

0 Response to "How To Cut 1/8 Inch Steel Plate"

Post a Comment